Children’s Hospital of Philadelphia (CHOP)

Roberts Center for Pediatric Research

Project Type: Hospital

Service: Value Coordination

Client: Children’s Hospital of Philadelphia

Stats: 250,000 sf / $300 million / year: 2017

**Work performed during employment at StructureTone

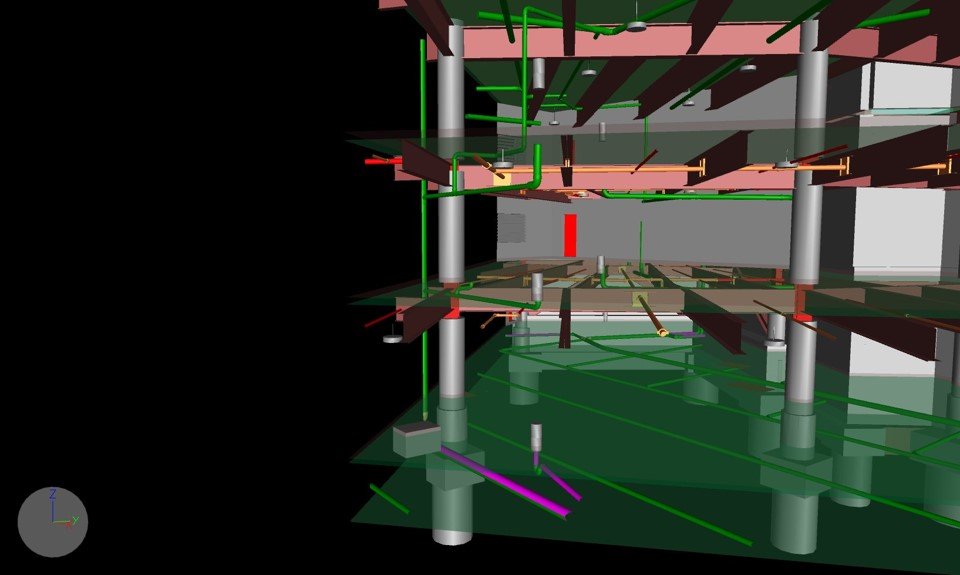

The Roberts Center for Pediatric Research includes a 480,000-square-foot office tower containing clinical research and administrative office space. The tower sits on a 190,000 sf, three-story plinth with parking, MEP and a loading dock.

Our Team Coordinated the project and shop drawings during Construction Document phase. The fully coordinated drawing was sent to the subcontractors, who validated the drawings and resubmitted for signoff.

In this case, the fabrication and installation were started almost right after subcontractors received the drawing, accelerating the schedule.

During the Pre-Coordination process, we where able to optimize several parts of the design.

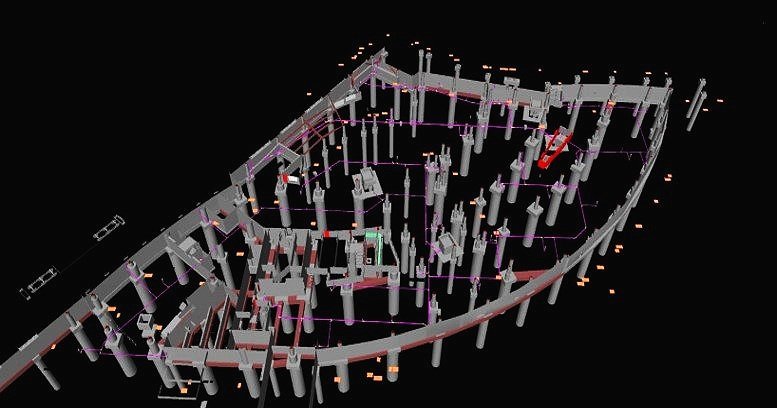

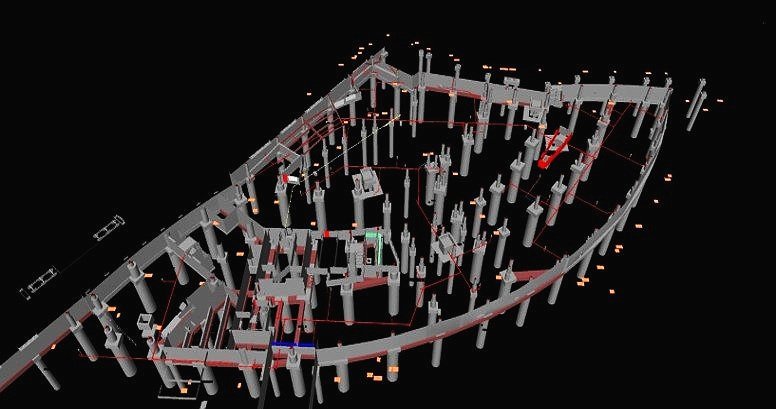

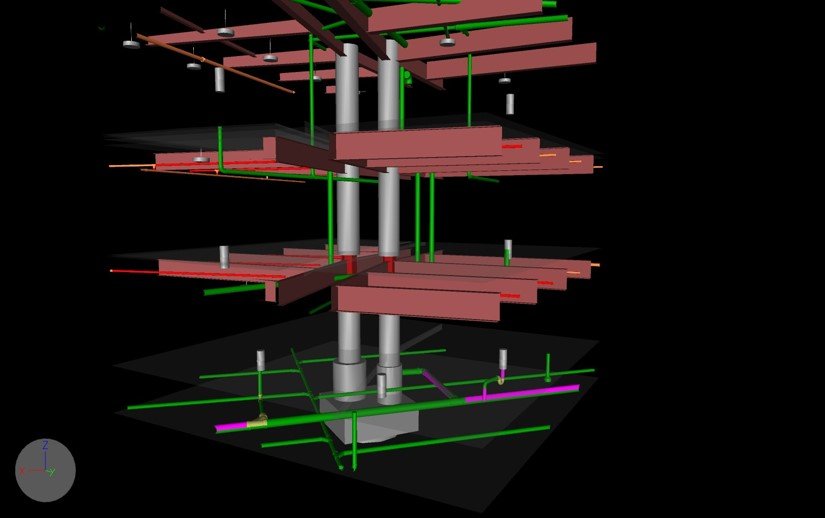

Underslab Coordination

During the design phase, Prefix optimized the underslab plumbing layout. Changes where signed off by engineers and incorporated into the CD set as supplemental drawings.

The changes resulted in a 30% reduction in Underslab Piping and trenching, which took 4-5 weeks off the schedule.

Since Prefix was coordinating the whole building, the design also allowed for leaner stack locations.

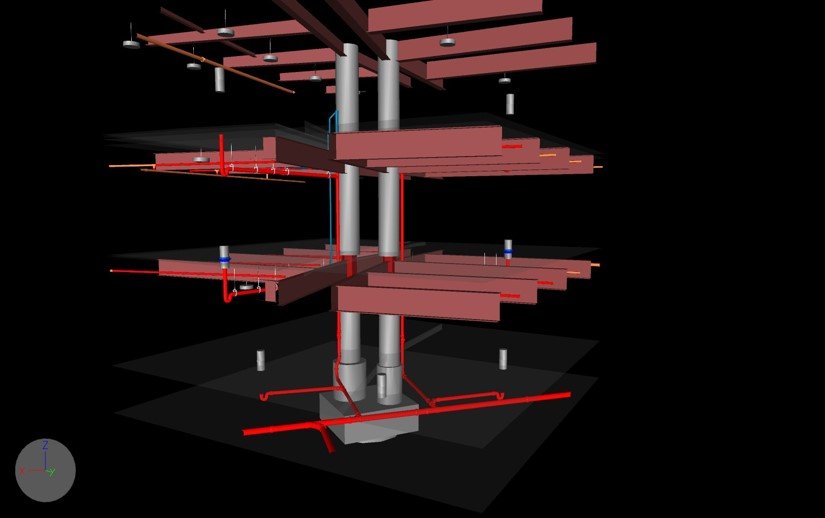

Stack Coordination

In the building, 50% of the piping reduced due to consolidated stack locations. Sleeves where coordinated with steel and architecture during design, avoiding 300 Potential RFIs on all stack locations.

.

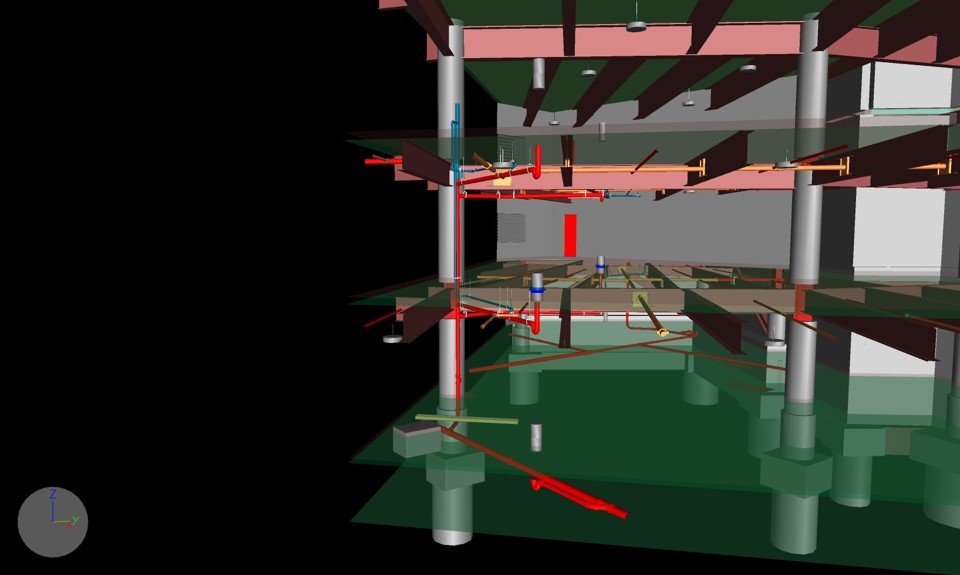

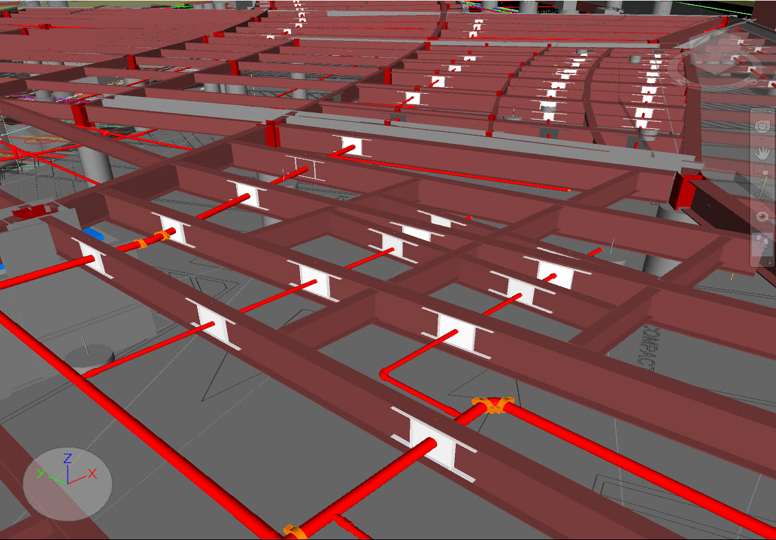

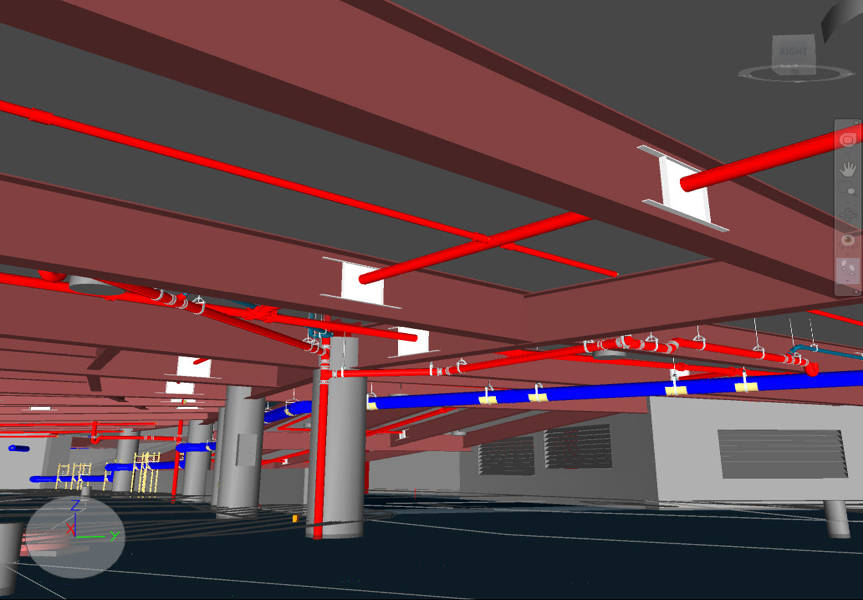

Garage Steel Coordination

The curvature of the building created unique challenges for fire protection in the Garage. Prefix modeled and coordinated Steel and FP, replacing swing joints with customized fittings.

•Pre-coordinated beam penetrations and changed beam sizes to avoid future MEP hits , which were released by the engineer as part of the contract document.

•Total 500+ beam penetrations and around 90 drains (for 3 floors) were saved before the purchase of the subs

•3-6 months coordination time were saved on beam penetration

•Underground was signed-off and installation was started 3 weeks after subs were brought on board.

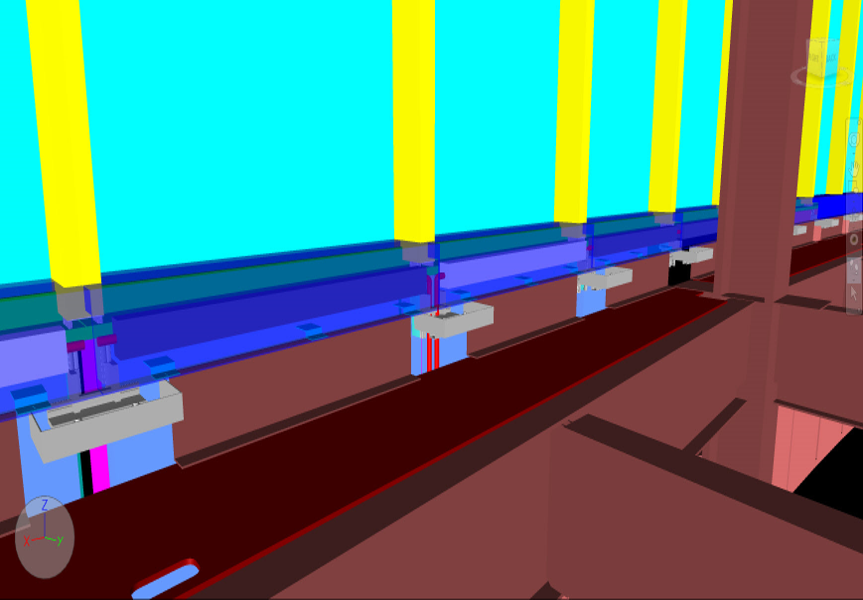

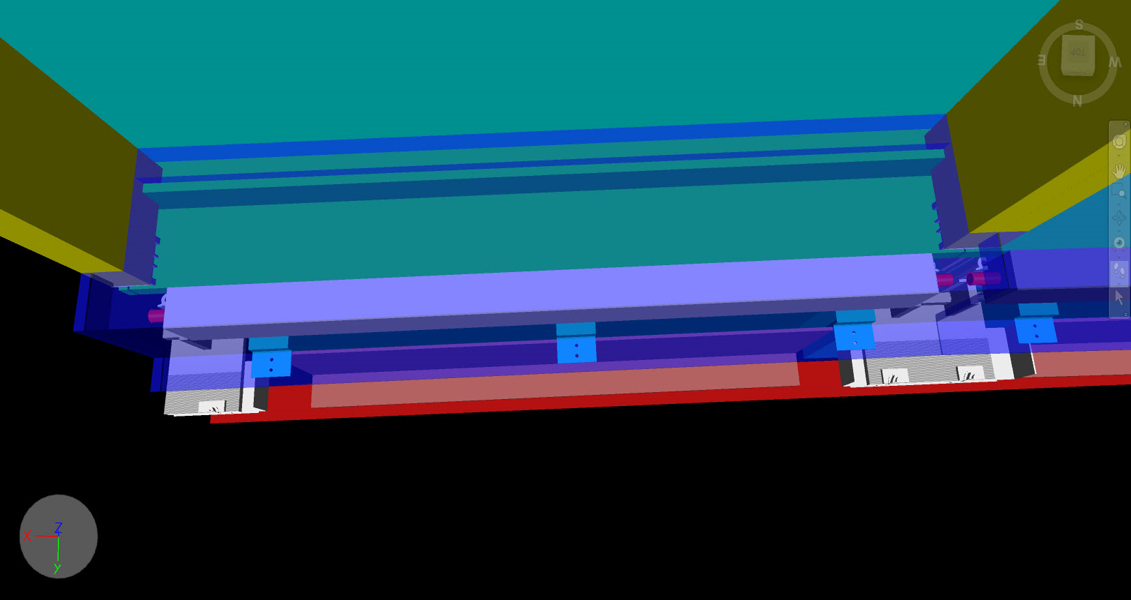

Design Pre-Coordination

•Original structural design called for curved pour stops

•During Design, we found curved pour stops and heating elements in curtain wall would not be aligned with curtain wall interior finish.

•Prefix recommended straight bent plate of each curved curtain wall joint, so heating element would be squared with interior finish.

•Structural engineer incorporated the recommendation into the contract document prior to purchase of structural subcontractor.

•This saved months in the future schedule and cost ($3M was estimated according to the architect)

Design Pre-Coordination

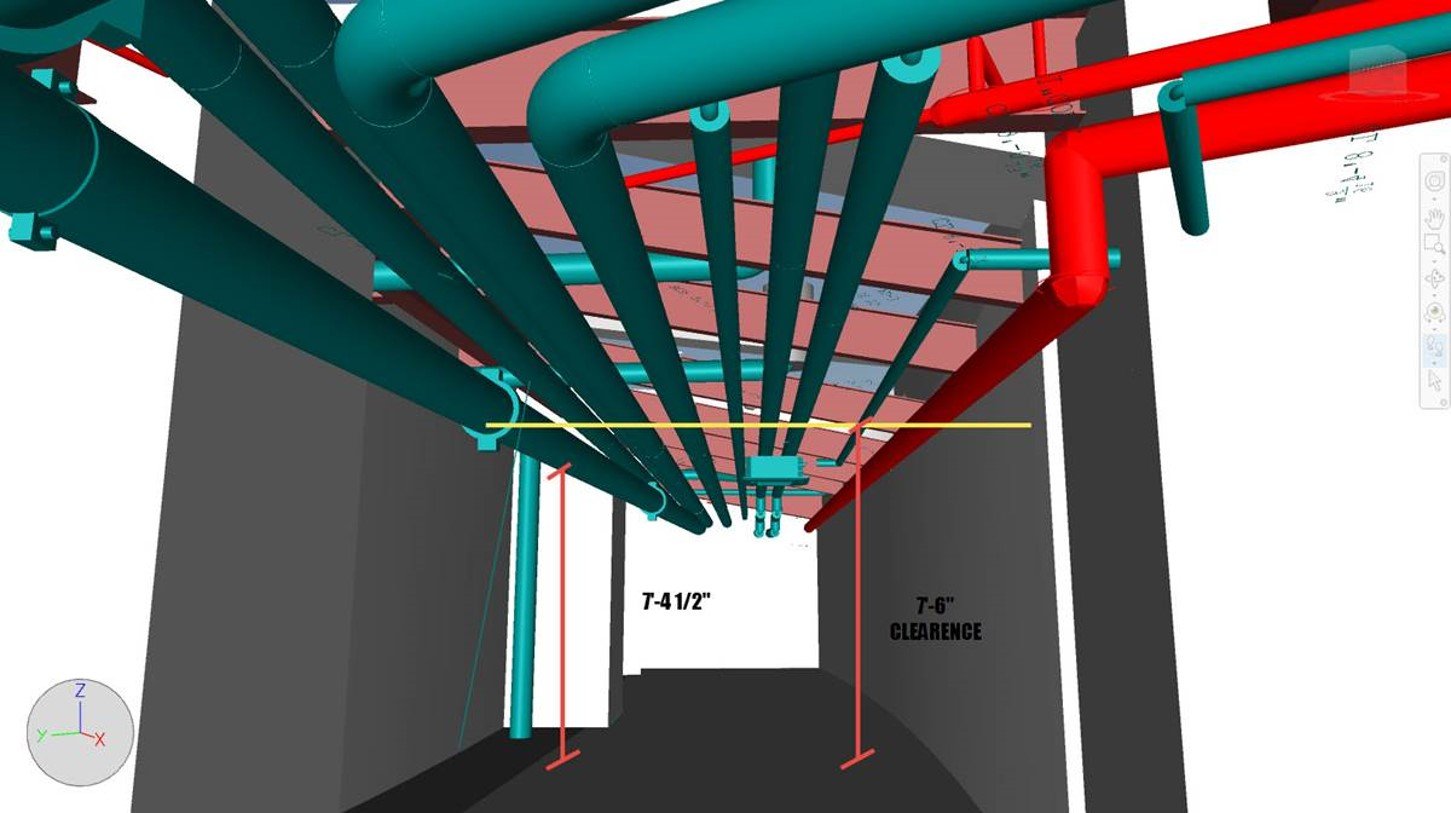

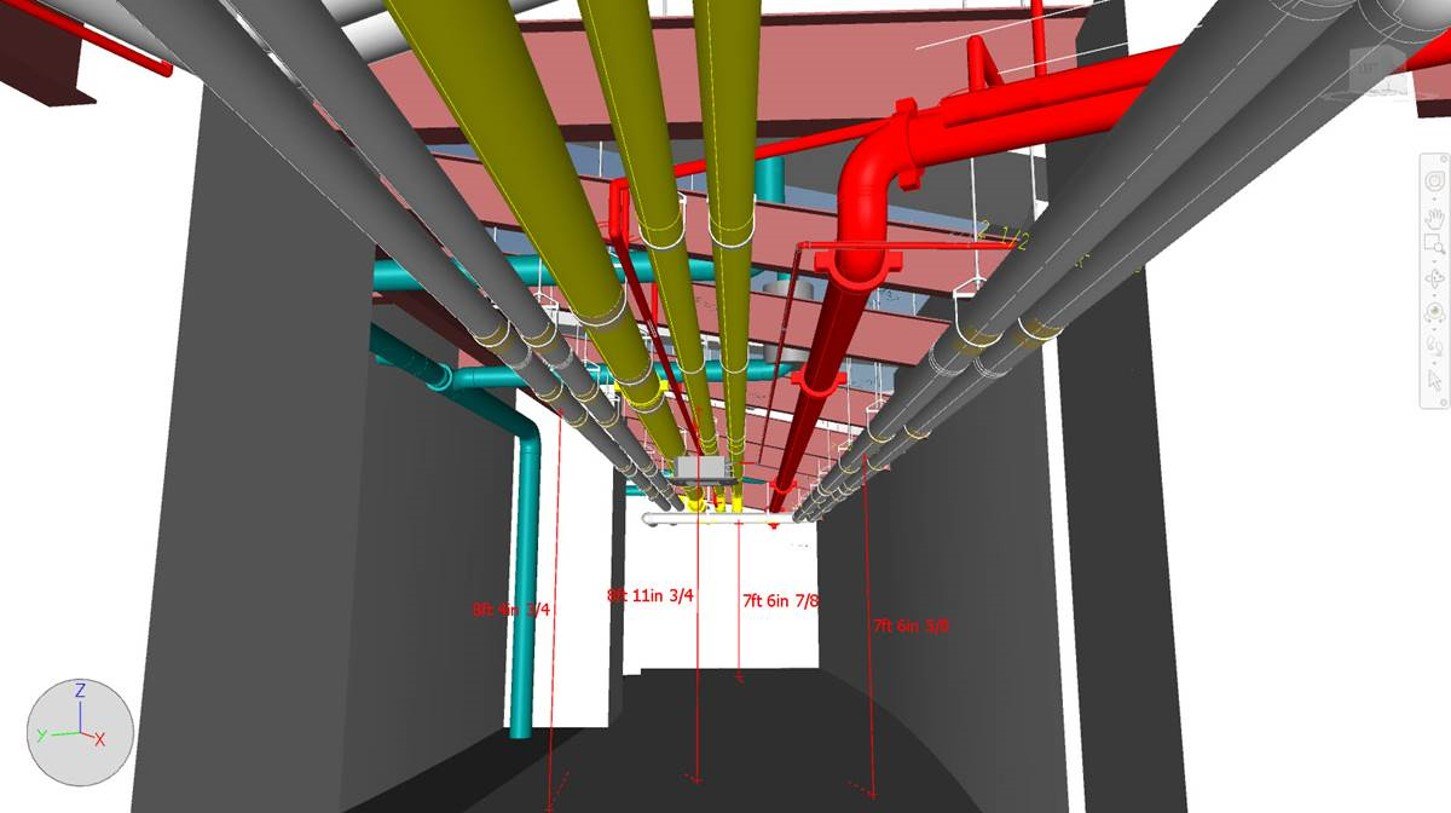

Prefix found coordination solutions several other tight locations throughout the building. A service corridor with a clearance requirement of 7’ 6” went through multiple redesigns with no solution. Prefix found and detailed a solution in under 48 hours.